Peer-reviewed technical guidance for design teams and building operators.

Status: Completed

Funding Sources: CBE Industry Consortium ASHRAE

Project Objective

Develop an ASHRAE Design Guide on Underfloor Air Distribution (UFAD) Systems. This research was conducted in collaboration with the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) as defined in the ASHRAE Research Project 1064-RP.

Project Results

The newest version of the Design Guide is available from the ASHRAE bookstore: http://www.techstreet.com/ashrae/products/1859223.

An ASHRAE Professional Development Seminar (PDS) on UFAD Design based on the Guide has also been developed and is offered periodically at ASHRAE meetings.

The UFAD Design Load Cooling Tool is described in detail on this page, and you can access the tool here.

Significance to Industry

UFAD technology has experienced rapid growth in North America because of the broad range of benefits that it offers over conventional ceiling-based air distribution. Although in recent years there have been an increased number of publications on this technology, designers of UFAD systems previously had largely developed guidelines of their own. A comprehensive design guide that is accessible to the design and engineering community was needed to support the continued development and growth of this promising technology.

This project developed the first ASHRAE Design Guide on UFAD and TAC technology and made it available to the professional design and engineering community at large. This design guide was first published in December 2003. In 2013, an updated UFAD Design Guide was published by ASHRAE.

Research Approach

This project involves the evaluation and synthesis of an extensive body of knowledge that has been developed by UC Berkeley and affiliated research organizations over a period of over 20 years. The development of the Design Guide was reviewed by CBE industry members and overseen by ASHRAE’s technical committee responsible for the project. Extensive comments and suggestions from industry were incorporated into the final version.

The Design Guide’s comprehensive contents includes chapters on air distribution, thermal comfort, underfloor plenums, controls, operation, maintenance, energy use, construction, commissioning, costs, perimeter systems, standards, codes, design methodology, and the LEED Rating System. The Guide also includes information on and Task/Ambient Conditioning (TAC) systems.

Performance of Underfloor Air Plenums

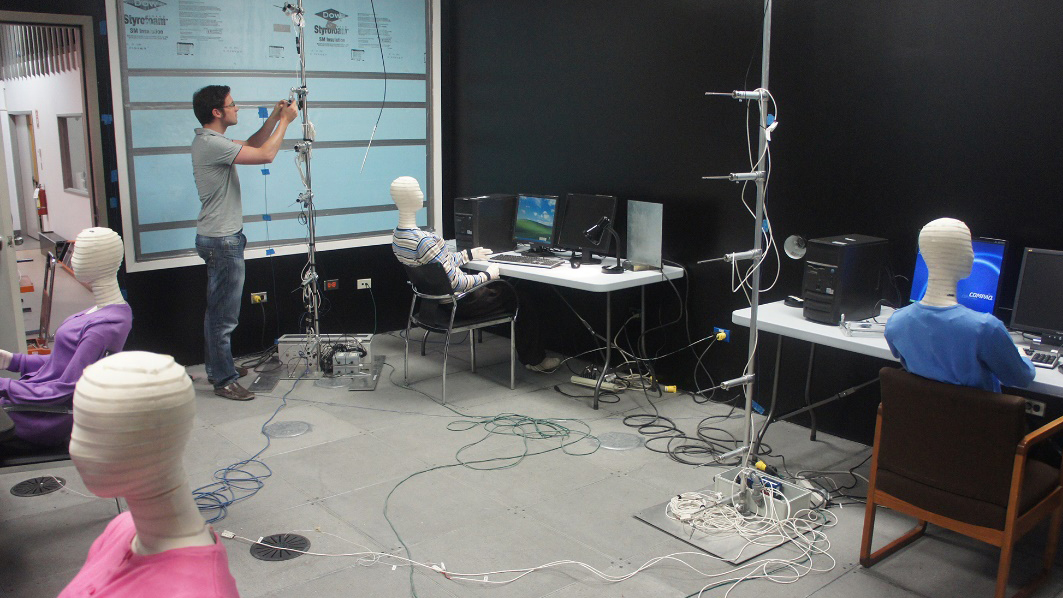

In this research area a number of full-scale field experiments have been conducted to investigate the airflow and thermal performance of underfloor air supply plenums. CBE maintains a full-scale UFAD test facility, consisting of a 22-foot by 74-foot by 1-foot high plenum. The test bed includes complete HVAC and data acquisition systems. CBE also utilizes computational fluid dynamics modeling to study plenum performance, including air flow and thermal transfer.

UFAD Room Air Stratification (RAS) Model Development

In this project a simplified model has been developed to estimate thermal stratification as a function of air supply volume and heat loads (for cooling conditions) for both interior and exterior zones served by a UFAD system. The model was developed from fluid mechanics principles derived from well developed displacement-ventilation theory, modified appropriately for the differences inherent in the UFAD approach. Detailed full-scale experiments have been conducted to support model development and verification and to better understand the impact of various design and operating conditions such as diffuser arrangements, supply air temperatures, and airflow rates.

UFAD Technology Transfer Program

This project supports the continuous maintenance of CBE’s Underfloor Air Technology website, and efforts by CBE researchers to respond to the large number of requests for information on UFAD from CBE industry partners and the building industry at large.

UFAD Design Load Cooling Tool

CBE’s research team has developed a simplified, practical design procedure and associated online tool to determine cooling load requirements for underfloor air distribution (UFAD) systems. The tool is described in detail on this page, and you can access the tool here.

Publications and Reports

Bauman, F., T. Webster, and H. Jin, 2006. Design Guidelines for Underfloor Plenums. HPAC Engineering, July. http://hpac.texterity.com/hpac/200607/?pg=30

Bauman, F., T. Webster, and D. Dickerhoff, 2008. Air Leakage Test Report EPA Region 8 Headquarters, Denver, Colorado. CBE Summary Report, August. https://escholarship.org/uc/item/9hf9320r

Webster, T., and F. Bauman, 2006. Design Guidelines for Stratification in Underfloor Air Distribution (UFAD) Systems. HPAC Engineering, July. http://hpac.com/ventilation-iaq/design-stratification-ufad

Bauman, F., T. Webster and P. Pecora, 1999. How Low Can You Go? Air Flow Performance of Low-Height Underfloor Plenums. CBE Summary Report, October. https://escholarship.org/uc/item/5rx3p5w4

Webster, T., and F. Bauman, 2006. Design Guidelines for Stratification in UFAD Systems. HPAC Engineering, June. https://cbe.berkeley.edu/wp-content/uploads/2018/09/7.pdf