Innovative control sequence for building automation systems widely applicable today.

Status: Current

Funding Sources: NYSERDA CalNEXT CEC PIER program CBE match funding

Project Objective

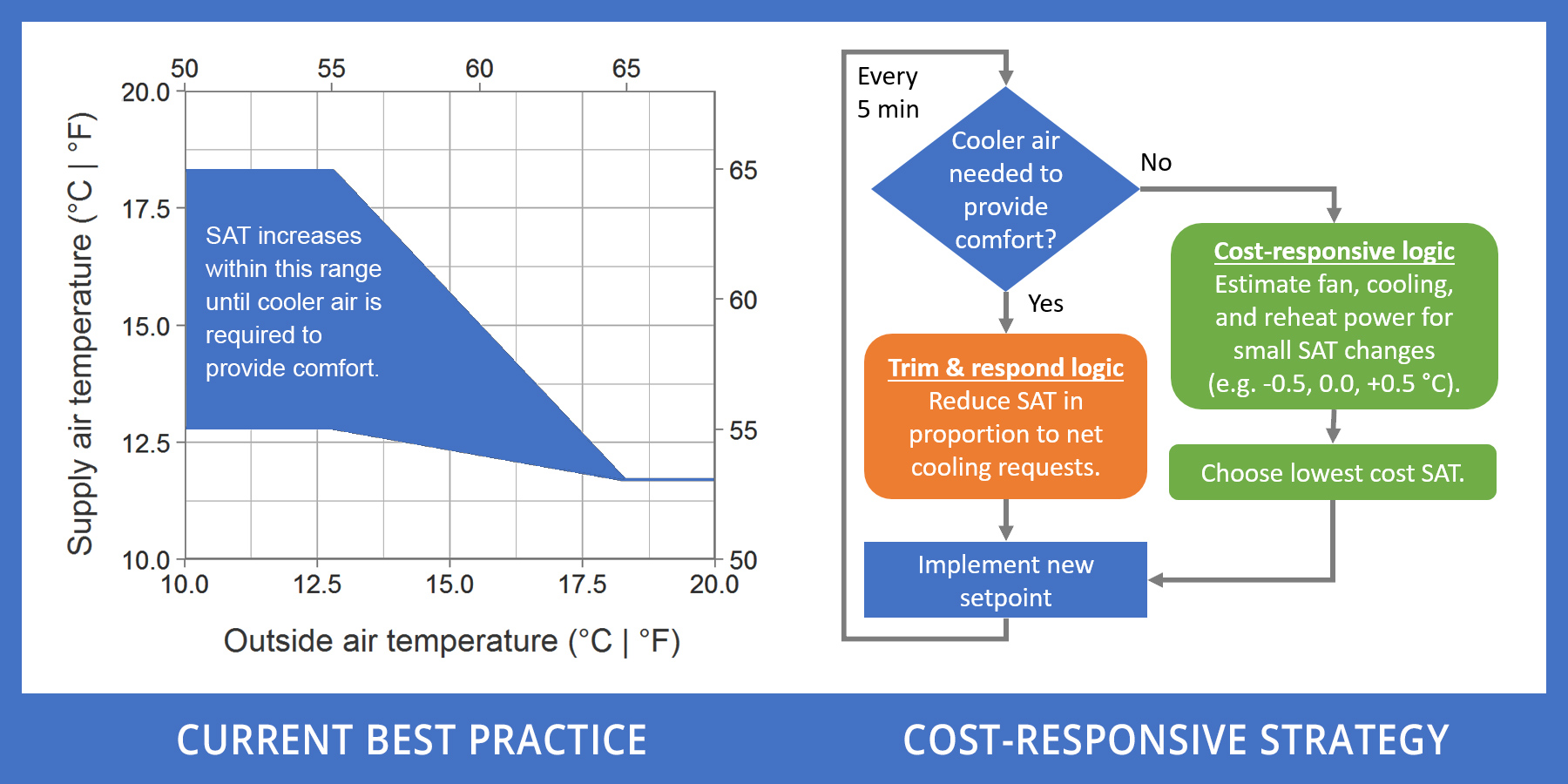

The goal of this project was to develop and test a control strategy that identifies the optimal supply air temperature for an air handling unit.

Project Results

A six-month randomized, controlled trial of this new control strategy reduced total HVAC energy costs by approximately 29%, when normalized to the typical annual climate data for this location and operating only during typical office hours (8 am – 6 pm). Energy savings occurred at all outside air temperatures, but were the highest between 16°C (60°F) to 24°C (75°F). These findings indicate that the current industry best practice control strategy does not use the optimal energy cost point under most conditions. This new control strategy is a valuable opportunity to reduce energy costs, at little initial expense, while avoiding more complex approaches, such as model predictive control, that the industry has been hesitant to adopt.

A demonstration of this low-cost control strategy, applicable to the most prevalent HVAC systems in North America, reduced energy use by 29% when normalized to standard annual climate data.

Significance to Industry

Variable air volume (VAV) HVAC systems dominate the commercial building market but have widely varying performance, with a well-documented performance gap. Two recent studies by Lawrence Berkeley National Lab (LBNL) and the California Energy Commission (CEC) reported a wide variation in energy performance for various typical supply air temperature (SAT) reset strategies (4-15% variation in HVAC energy). Existing SAT reset strategies have three inherent deficiencies that explain the lack of market uptake and sub-optimal real world energy performance: (1) they include simplifications and assumptions about the relationship between SAT and total heating, ventilation, and air conditioning (HVAC) energy cost , (2) they require tuning of key parameters whose optimal values differ for every building and vary over the life of the building, and (3) there is no easy way to determine what those optimal settings are and whether tuning is improving savings or not.

This project will (1) develop the CORE control sequence for application in humid climates, (2) refine algorithms for integration into various BAS control systems (local and third party approaches), (3) implement CORE demonstration at the Cornell University campus, and (3) support a path to market.

Research Approach

This project developed the CORE (Cost Optimized REset) solution, a new cost-responsive supply air temperature reset strategy for multi-zone variable air volume systems, simple enough to implement within a typical building automation system (BAS). CORE dynamically estimates the cost of fan, heating, and cooling energy at three different SATs (current, higher, lower) and chooses one with lowest cost as the setpoint. It then iteratively moves in the direction of least cost, while subject to the same constraint to maintain comfort conditions as the current industry best practice. CORE uses existing sensors that are commonplace in a typical VAV system without requiring new equipment installation, and it can be implemented within native BAS programming languages. Our research team developed and demonstrated first iteration of CORE for the California Energy Commission and showed 29% energy savings in one demonstration building.

The strategy was developed with the intent that CORE be simple enough to implement within existing building management systems. This approach aimed to minimize complexity so that the strategy could be implemented within building automation system software and hardware, by typical controls contractors. It was tested in a seven-floor, 140,000 ft² office building, and the team compared the energy costs to the industry best practice control strategy in a daily-randomized controlled trial over a six-month period.

Since the completion of this field study, we have started additional pilot tests for this control strategy, in collaboration with TRC, Kaiser Permanente and Fordham University, with funding from NYSERDA and CalNEXT.

Publications and Reports

Raftery, P., Li, S., Jin, B., Ting, M., Paliaga, G. and Cheng, H. 2018. Evaluation of a cost-responsive supply air temperature reset strategy in an office building. Energy and Buildings, 158(1), 356-370. https://escholarship.org/uc/item/1fk2m3v6 http://dx.doi.org/10.1016/j.enbuild.2017.10.017

Raftery, Paul. 2017. Saving energy in variable air volume systems in existing buildings: supply air temperature setpoints. LinkedIn Pulse. 21 November 2017. https://www.linkedin.com/pulse/saving-energy-variable-air-volume-systems-existing-supply-raftery/

Presentations

Raftery, P., S. Li, B. Jin, M. Ting, G. Paliaga, and H. Cheng. Cost Responsive Supply Air Temperature Reset Strategy. Center for the Built Environment, UC Berkeley, May 2017.