Companies aspiring to sustainability and wellness leadership prioritize occupant health and comfort in their office buildings. This often includes strategies for managing workplace indoor environmental quality (IEQ), which has emerged as a key component of building rating systems such as WELL and LEED. Some rating systems require monitoring of indoor environmental conditions as part of their evaluation procedure, but undertaking those measurements in a reliable manner can be challenging. In this post we discuss why continuous monitoring technologies are ideal for evaluating building IEQ performance.

Common IEQ parameters such as temperature and sound pressure in office buildings vary significantly– daily, weekly, and seasonally. However, sampling requirements found in many standards and monitoring protocols mandate measurements be conducted at a few specific locations within the building, once or a few times a year. As part of a building certification process, companies often hire a consultant with access to expensive measurement devices to perform a measurement ‘sweep’ over a single day. The resulting data is then used to determine a building’s annual performance and compliance, despite it only being a snapshot of the conditions experienced by occupants.

Recent innovations in sensor technologies and systems that provide continuous IEQ monitoring mitigate these measurement challenges. These systems can autonomously measure many common IEQ parameters without requiring special knowledge for installation and operation. One example is the SAMBA IEQ Monitoring system developed by CBE’s colleagues at The University of Sydney. Designed specifically for IEQ assessments of commercial office buildings, costs were kept low enough to permit multiple units to be deployed across an office or building to measure key environmental parameters as experienced by occupants throughout the year. Despite the strong industry interest in continuous monitoring, some have raised concerns over the use of low-cost devices for building performance assessments due to questions about sensor accuracy.

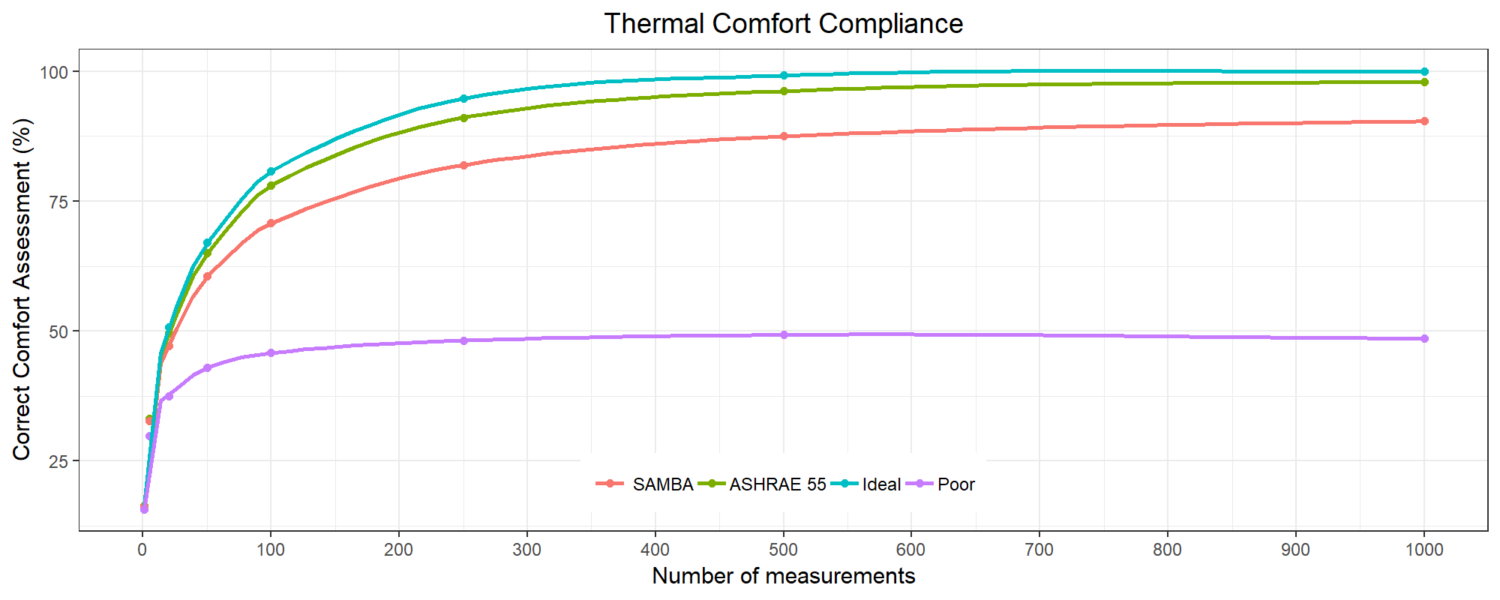

To address these concerns, researchers at CBE set out to determine whether low-cost systems can provide sufficient insight into IEQ variability for the purpose of long-term performance assessments in buildings. The analysis was based on three months of field measurements of thermal comfort (based on predicted mean vote, or PMV) from 60 continuous IEQ monitoring devices distributed across 24 office buildings. The measurements were compared to existing standards and rules-of-thumb with varying levels of accuracy. Using the field data and simulations of the comparison standards, we performed a Monte Carlo simulation to compare the ability of all these systems to correctly classify the thermal environment as comfortable or uncomfortable using five-minute interval data.

Graph of thermal comfort classification comparing the SAMBA system to other measurement standards.

One baseline was provided by a perfectly precise measurement system (“Ideal” in the graph above) with no error, providing 100% correct compliance classification when continuously monitoring. In comparison, the SAMBA device achieved 94% correct classification. Results from a system with very low accuracy were only 50% correct. However, comparing the monitoring systems based on sensor uncertainty and the number of measurements during the monitoring period yielded interesting results. Even with sensor inaccuracies, the low-cost continuous monitoring system was demonstrated to be much better at characterizing long-term thermal comfort than an approach based on fewer measurements with laboratory-grade instruments. For example, approximately 250 spot measurements would be required with perfect “Ideal” systems to match SAMBA’s level of performance over the three-month monitoring period. With ASHRAE-55 equipment specifications, this would require 350 samples, equal to a spot measurement made approximately every two days.

The key takeaway of this research is that continuous monitoring technologies — even with some sensor inaccuracies —provide a better assessment of a building’s long-term indoor environmental quality. Devices like SAMBA, or commercially available systems such as Senseware or Awair, are valuable tools for understanding the indoor environments of commercial buildings. Whilst spot measurements may still be necessary for forensic investigations, continuous monitoring is better at quickly identifying indoor environmental quality problems when they occur. This allows building operators to efficiently target resources to resolve issues. Instead of demanding tight tolerances in equipment measurement specifications, attention should instead be directed towards exploring how continuous IEQ monitoring systems can best be used within (or side-by-side with) the conventional approaches to IEQ performance assessments found in standards and guidelines that evolved specifically for insitu spot measurements.

To learn more about this research, see our two papers in Building and Environment, on the SAMBA continuous monitoring system, and on the comparison to spot measurement methods.

Main image: SAMBA Continuous Monitoring System.