Research to support the development of impact reduction policies around embodied carbon.

Status: Current

Funding Sources: California Air Resources Board

Project Objective

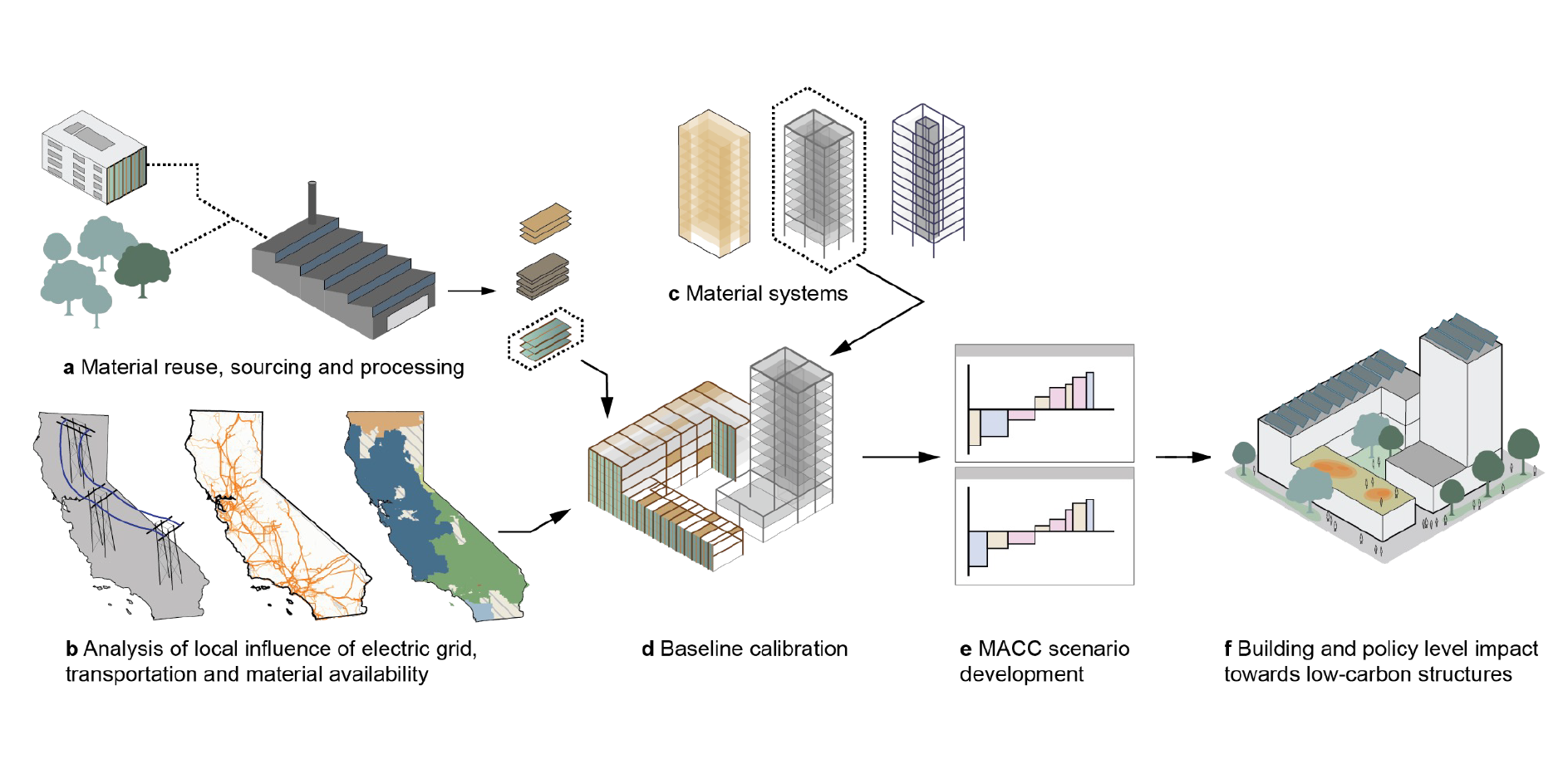

This work aims to develop resources and investigate scalability, risks, barriers and opportunities of various impact reduction strategies for construction materials used in the construction of buildings across the State of California. This will include development of marginal abatement cost curves (MACCs) to support policy development by summarizing greenhouse gas (GHG) reduction strategies and their associated costs for materials used within the initial construction of buildings. We will also investigate the GHG reduction potential for material efficiency, reuse, and substitution strategies while assessing material supply chain interventions that can be implemented at scale.

Significance to Industry

The built environment has been identified as a critical sector for combatting the worst consequences of climate change as it contributes 37% of global energy and process-related greenhouse gas (GHG) emissions. These emissions originate from a variety of activities that happen throughout all stages of a building’s lifespan. A significant amount of GHG emissions is associated with the initial material production, sourcing and construction activities for the building which occur over a relatively short timeframe compared to the full lifespan of the building. Mitigating these impacts is critical as they occur before and during construction, therefore effective solutions can yield immediate reductions of GHG emissions and contribute to near-term climate targets.

Governments, including California, are setting targets to reduce GHG emissions while exploring which cost-effective strategies should be encouraged or incentivized through policy initiatives. By the end of 2028 California has a mandate to impose a strategy for reducing the GHG emissions of building materials by 40% by the end of 2035. This initiative demonstrates California’s leadership in the transition to a net-zero carbon built environment within the United States. California and industry practitioners need to understand what strategies to pursue and prioritize to meet these targets.

Research Approach

The project is organized into several connected tasks to achieve the stated goals. Throughout these tasks we will employ a combination of economic, life cycle assessment (LCA), material stock and material flow analysis methodologies to deliver the tasks effectively.

The first task of the project will focus on identifying the building materials and products that will be the main subjects of this research. Consumption trends across California will be reviewed to identify the materials and products that contribute to at least 80% of upfront [A1-A3] embodied carbon impacts for new construction buildings on average. Once the materials and products have been selected, functionally-equivalent substitution hierarchies (FESHs) will be developed to identify and rank functionally equivalent substitutions for materials and products that are likely to lead to net-reductions of GHG emissions.

The next phase includes a literature review and construction coordination for interventional analysis. This work will bridge scientific literature and industry experience to ensure the proposed interventions are grounded in scientific evidence while being feasible and appropriate within a Californian context.

In the third phase, data collected from literature and industry will be assembled into a database to develop MACCs. A formatting and normalization procedure will be developed that allows the data to be compared and the impact of the interventions to be assessed. Normalization methods will be compared to ensure appropriate comparisons of interventions across the supply chain of a single material and of interventions across a functionally equivalent substitution hierarchy. The completed dataset will quantify the GHG impacts or reduction potential and the associated costs for implementing the studied interventions using life cycle assessment (LCA) software with an appropriate background dataset.

The developed MACCs will delineate which measures lead to increases in cost incurred at the construction location, and will be identified through a constructability analysis and consultation with industry experts as part of technical advisory committee meetings and engagement. We will consider a wide variety of factors that can lead to changes in construction cost, for example material choice and quantity, construction duration and schedule, skill level and number of workers, and required equipment. Appropriate efforts will be made to investigate the degree to which proposed interventions lead to knock-on, secondary or ripple effects that may result in reduced by-products or increased emissions in processes across multiple-function / multi-product systems or supply chains.