Reduce natural gas consumption in large commercial buildings with a path to cost-efficient solutions.

Status: Completed

Funding Sources: California Energy Commission EPIC Funding CBE Members In-kind funding from Genentech and Price Industries

Project Objective

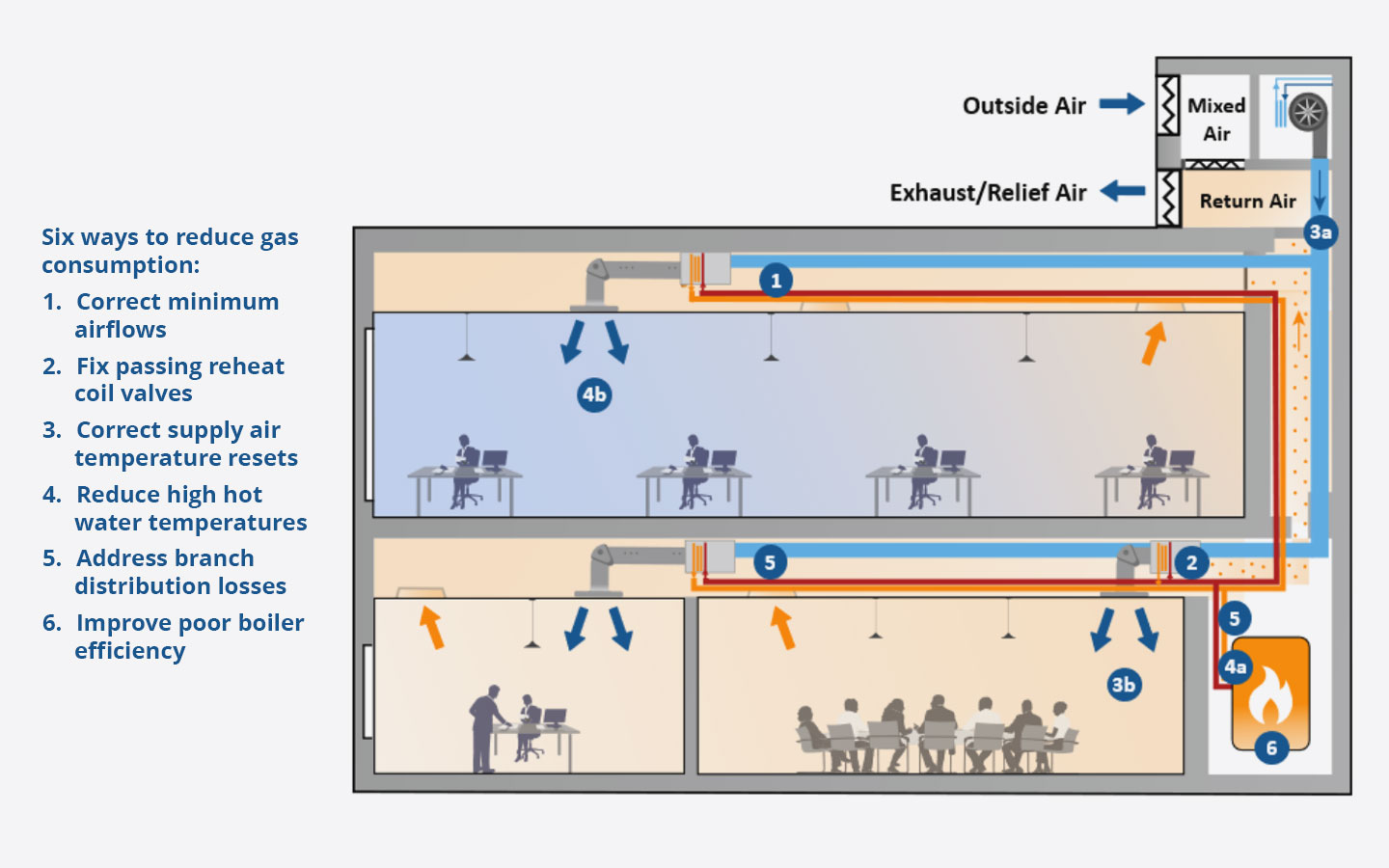

The research team demonstrated and evaluated a package of low-cost measures to reduce natural gas consumption by commercial building heating systems — a significant source of greenhouse gas emissions. Findings from field tests and data analyses were used to develop a web-based screening tool, a design guide and policy recommendations to accelerate technology adoption across diverse portfolios of buildings with varied infrastructures. This approach offers a solution in terms of cost and convenience more accessible and scalable than replacing entire HVAC systems for full electrification.

Project Results

The final report and numerous publications are listed below. A short video presentation on key findings is also linked below the publications.

This project demonstrated deep reductions in the carbon intensity of natural gas space heating in existing large buildings in a scalable manner by focusing on deep efficiency measures — without replacing entire HVAC systems or performing a gut renovation. Through a combination of ‘Deep Decarbonization re-Design’ measures in two existing office buildings (120,000 and 110,000 ft²) annual gas consumption was reduced by 70%, plus substantial electricity savings. When combined, the measures reduced costs by $110,000 per year ($0.5/ft².yr) at current utility rates.

Significance to Industry

Natural gas consumption for space and water heating represents two-thirds of CO2 emissions from commercial buildings. A previous CBE study of a large office building in San Mateo County revealed that with a gas-fired boiler serving hot-water reheat, only 17% of the energy cost went towards useful heating, while 83% was wasted due to piping losses and boiler inefficiency. As these are the most prevalent systems in commercial buildings, addressing these inefficiencies and losses represents a major opportunity for reducing costs and greenhouse gas emissions.

Although hot-water reheat is a predominant system installed in existing large buildings, we know of no viable solutions to decarbonize these systems without entirely replacing them. This is not feasible from a cost perspective (even at boiler and/or air handling unit end-of-life) as it effectively means replacing the entire HVAC system. This includes the HVAC terminal units serving individual rooms, and the associated disruption to occupants that modifying those would entail. However, in order to meet our climate goals, it is essential that we determine a pathway to cost-effectively reduce the carbon emissions associated with these systems.

Research Approach

The four central project tasks included: (1) field testing energy-saving measures at the demonstration sites (two commercial office buildings, 120,000 and 110,000 ft2) including controls upgrades, valve replacements, and boiler replacement; (2) conducting lab testing to evaluate measures and incorporate the findings into new design guidance; (3) evaluating the scalability of our solutions across datasets of a larger portfolio of buildings; and (4) developing a screening tool, design guide and other resources for market transformation. CBE will play the lead role in the project management, technology development and evaluation, lab testing, data analysis, screening tool development and outreach activities. The upgrades related to controls were based on ASHRAE Guideline 36-2021, ‘High-Performance Sequences of Operation for HVAC Systems.’

CBE collaborated on this research with numerous CBE industry partners and others. Price Industries provided in-kind support at its HVAC testing laboratory, and CBE’s consortium members provided additional match funding. Taylor Engineering led the implementation at the demonstration sites, provided expert practical technical expertise, and led the writing of the guide. TRC oversaw the installation of monitoring equipment, data acquisition, and policy recommendation tasks. The Western Cooling Efficiency Center (WCEC) at UC Davis conducted field measurements to validate the method and assess loss pathways in more detail in the field. CBE partner Genentech was also a key contributor. Finally, the team will work with additional partners to implement our solutions more widely following completion of the field demonstration, scalability evaluation, and development of resources for building operators.

Publications and Reports

Raftery, P., Cheng, H., Singla, R., Peffer, T., Vernon, D., Duarte, C., et al. (2024). Reducing Gas Consumption in Existing Large Commercial Buildings. Final project report. UC Berkeley: Center for the Built Environment. https://escholarship.org/uc/item/3fh0x2vm

Raftery, P., Singla, R., Cheng, H., & Paliaga, G., (2024). Insights from Hydronic Heating Systems in 259 Commercial Buildings. Energy and Buildings (321) https://www.sciencedirect.com/

science/article/pii/ S0378778824006595 Cheng, H., Raftery, P., & Wendler, P. (2024). Are We Prioritizing the Right Thing? Cutting Carbon Emissions in California’s Large Office Buildings Before Installing a Heat Pump. 2024 ACEEE Summer Study on Energy Efficiency in Buildings (in press). https://escholarship.org/uc/

item/9cd4c4zt Cheng, H., Raftery, P., & Wendler, P. (2024). Re-optimizing Optimal Start and Morning Warmup. ASHRAE Journal, 66(8). https://escholarship.org/uc/

item/6zw3x4rt Cheng, H., Wendler, P., & Raftery, P. (2024). Hot Water Heating: Design and Retrofit Guide. UC Berkeley: Center for the Built Environment. https://escholarship.org/uc/item/8m88d92j

Singla, R., LaPalme, G., & Chappell, C. (2024). Heating Hot Water Policy Recommendations. UC Berkeley: Center for the Built Environment. https://escholarship.org/uc/item/7sf76298

Raftery, P., Vernon, D., Singla, R., & Nakajima, M. (2023). Measured Space Heating Hot Water Distribution Losses in Large Commercial Buildings. UC Berkeley: Center for the Built Environment. https://escholarship.org/uc/item/46h4h28q

Vernon, D., McMurry, R., & Raftery, P. (2024). Heating Hot Water Distribution Heat Losses – Detailed Measurement. ASHRAE Transactions, Proceedings from the ASHRAE Winter Conference, Chicago, 130 (Part 1).

https://escholarship.org/uc/item/7n6893n6 Wendler, P., Raftery, P., & Cheng, H. (2023). Variable Air Volume Hot Water Reheat Terminal Units: Temperature Stratification, Performance at Low Hot Water Supply Temperature, and Myths from the Field. UC Berkeley: Center for the Built Environment. https://escholarship.org/uc/item/6b9590qr

Roa, C., Raftery, P., Singla, R., Pritoni, M., & Peffer, T. (2022). Detecting Passing Valves at Scale Across Different Buildings and Systems: A Brick Enabled and Mortar Tested Application. Lawrence Berkeley National Laboratory.

http://dx.doi.org/10.20357/B7VP5H

https://escholarship.org/uc/item/4xq5b54tLamon, E., P. Raftery, P. & Schiavon, S. (2022). Boiler Retrofits and Decarbonization in Existing Buildings: HVAC Designer Interviews. Report for the California Energy Commission, also included in Proceedings, ACEEE Summer Study on Energy Efficiency in Buildings, Panel 5. August. https://escholarship.org/uc/item/6k4369zv